ROTOMOLDING

LifeArk components are manufactured using rotational molding

Rotational molding is a globally available manufacturing technology to mass produce strong, buoyant parts quickly and economically

This image was taken at the aftermath of the 2011 earthquake and tsunami in Tohoku, Japan

Image: Leo Cool/ Creator: Kenji Shimizu/ Copyright: AP2011

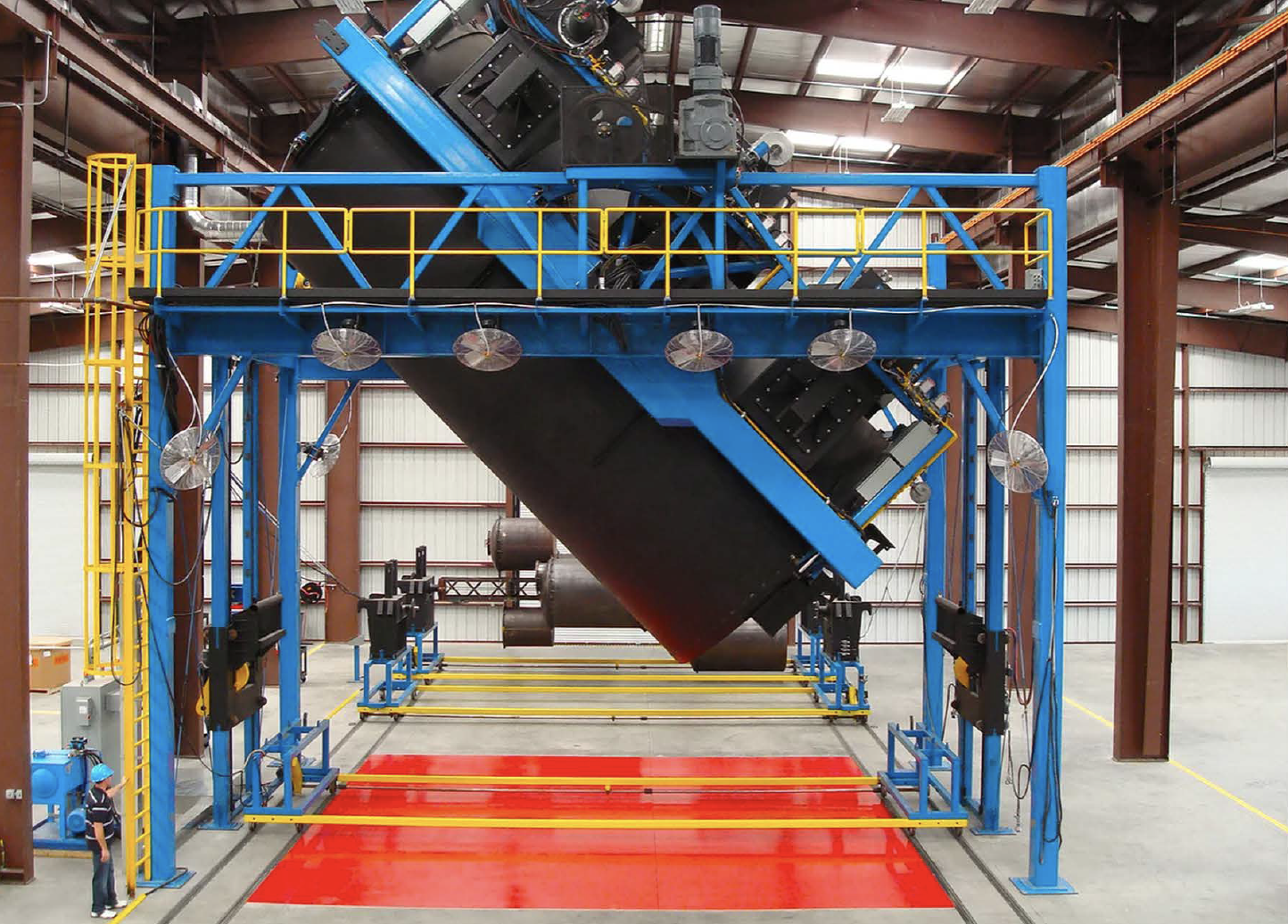

Innovative Rotational Molding, Inc.

LifeArk components are manufactured at our partner facility in Madera, CA

Custom Rock and Roll Machine in Madera Facility

Rotoline DC4.50 in Madera Facility

Rotational Molding Advantages:

Design flexibility allowing complex geometry

Low-Tech process

Tooling cost are less then other plastic molding methods

Parts offer strength, corrosion resistance and durability

Short lead times on production

Environmentally-friendly: no chemicals or dangerous toxins are released during production

Less material wastage compared with manufacturing with other materials like wood, metal or concrete